Technical Report for Ultrasonic Impact Surface Process.pdf Technical Report for Ultrasonic Impact Surface Process.pdf

If you are also interested in Ultrasonic Impact Treatment/Ultrasonic peening(UIT/UP) equipment,you can click here

1. About the technology

Due to the characters of material, the working depth of Ultrasonic Surface Process Equipment is from 0.1um to 1mm, with a surface smoothness of 0.02um and a 100um deep nanocrystal surface.

Seen from the processed materials such as Ti alloy, 40Cr, No.45 Steel and Al alloy, the equipment show its great effort. For instance, after processing, 40Cr gets a 0.15um surface smoothness and a 60um-deep surface nanocrystal.

2. Data of different materials after processing

a. No.45 Steel

|

No.45 Steel |

Smoothness Ra/μm |

Average

Ra/μm |

|

1 |

2 |

3 |

|

Original |

6.6 |

7.2 |

7.5 |

7.1 |

|

After Processing |

0.18 |

0.20 |

0.20 |

0.19 |

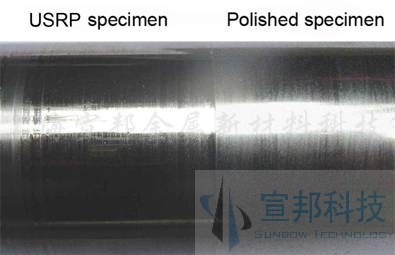

b. 40Cr

|

40Cr |

Smoothness Ra/μm |

Average

Ra/μm |

|

1 |

2 |

3 |

|

Polished |

0.36 |

0.35 |

0.34 |

0.35 |

|

After processing |

0.085 |

0.12 |

0.09 |

0.098 |

3. Parameters

|

Parameter |

Value |

Parameter |

Value |

|

Energy converter |

Piezoelectric

ceramic |

Cooling-down method |

Wind cooling |

|

Load voltage |

220V±10%,50Hz±5% |

Output power range |

50~300W |

|

Output power |

300W |

Output power step length |

Continuous |

|

Drive current |

0~3A |

Operating Mode |

Load consistence 85% |

|

Operating frequency |

20±2KHz |

Power box size |

350×200×250mm |

|

Amplitude |

15~50µm |

Power box weight |

7 Kg |

|

Application of force |

0~90N |

Operating temperature |

0 ~+35 ºC |

4. Surface Hardness Analysis

a. No.45 Steel

From the picture below we can see that, after processing, there is a apparent rise on the surface hardness while the further from surface ,the smaller the hardness is. Compared with the inner part, the surface hardness increases by 1 time and up to 200um deep part is enhanced.

b. 40Cr

Compared with the inner part, the surface hardness increases by 3 time and up to 100um deep part is enhanced apparently.

|